Quote:

2/27/07 Update: AquaMend has been a consistent winner in filling holes and building structure. Scroll down to the bottom to see the section specific to AquaMend.

As a result of working with both the Rubie's (plastic) helmet and various fiberglass kits, I've had a chance to experiment with various putties and spreads. I'm the kind of person who goes, "Okay, they used PC-7. But why? Is there something that's better?"

Here is a review of the materials I've used so far.

Bear in mind there are two epoxy material categories: putties and pastes. A putty is like a sticky clay. You can shape it in your hands. A paste is like peanut butter but stickier. Certain expoxies do not adhere to wet hands.

PC-7

Many tutorials use PC-7. It's a putty where you combine equal parts of "A" and "B" to form a gray paste which cures to a very dark gray. Applying it is fun. Because it doesn't adhere to wet surfaces, I could wet my hands and mix the PC-7. I recommend using latex gloves. The manufacturer recommends denatured alcohol instead of water but they felt water wouldn't harm the curing process.

Unfortunately I have not had good experience with this material. To give it the benefit of doubt, it has indeed been cold here in California so the temperatures have been colder than the 70 degrees F that PC-7 requires to cure. My only reasonably successful application was a thin layer, exposed to the sunlight. It seems to have fully cured in this case but you can still more or less press your fingernail into it.

In one particular application where I needed to reinforce the interior of a dome and add some length to the flange, the PC-7 eventually failed to bond completely; I was able to flex it but then it started breaking apart. You see, PC-7 contains an agent that gives it plasicity which may be great for repairing, say, shoes. But certain fiberglass resins aren't quite as flexible.

When it came to sanding and shaping, I found PC-7 to gunk up my files and sandpaper all too easily.

The flexibility does not help when you're priming it; the primer cracks off.

In the end, I used a putty tool and was able to remove chunks of it without too much effort.

Again, it may be that even though it got a lot of time in the sun, the temperature prevented it from fully curing.

PC-11

PC-11 is the marine fiberglass-repair cousin of PC-7. This dries white. Again, you combine equal parts of "A" and "B" but unfortunately water is not going to be a good resist because it's formulated to stick under water. This is not something you're going to wash off. I have not confirmed with the manufacturer of denatured alcohol would assist in its removal, so you should wear latex gloves -- perhaps even consider the stronger type, because the thin white latex gloves easiliy break.

PC-11 gets

everywhere so have a rag to wipe off excess and to clean off areas you accidentally touch with your hands. Not only is it a paste, it's extremely sticky, isn't resisted by water or dampness, so this is almost like playing with fire. If you make a mistake and can't clean it off, you'd have to wait for it to harden and then sand it off.

Now the beauty of PC-11 is that it's made for fiberglass repair, since many boats are made of fiberglass. Of course, it can repair other things, which makes it interesting for us, but the key thing to bear in mind is that it's seems very compatable with fiberglass resin -- and let me qualify that next.

When doing things like lengthening the flange of a fiberglass dome (some people seem to want to do this to cover the back of their necks, whereas it's possible to simply reposition the dome to do that. But in cases where someone casts a dome with a flange that is too short, lengthening it is a valid application) you are adding to the structure. Fiberglass has a degree of flexibility to it. Whatever you use to lengthen its structure would ideally have a similar degree of flexibility.

In the case of PC-7, it had too much flexibility and broke off. Conversely PC-11 literally became "one" with the fiberglass, and this earned my respect. I did not do much to create a rough surface for PC-11. It bonded with an incredible tenacity and I am unable to break it off. What's even better is that it sands very well despite its strength, and was of similar sandability to the fiberglass resin I was working with. Now different resin will have different wear resistance so your mileage will vary.

The problem with it being a paste is that until it hardens (like in an hour) you can only add length to your flanges in small increments. Once it starts to semi-cure (about 15 minutes) you can work with it a little because now it's semi-solid. It will still start to droop under its own weight. You'd have to reposition this every so now and then until your hour is up. What you are unable to accomplish during the curing process, you'd have to leave up for sanding.

With sanding, you will do yourself a great favor if you have a hand sander and 80 grit paper for shaping.

PC-11 is perhaps ideal for large surface areas, so if you suffer from a bad fiberglass casting, just paste PC-11 all over the place, smoothe it out with a spreader, allow to dry, and then sand it down to re-establish a smoother surface. But it can be difficult to control. There is, in fact, something better, which I will get to shortly, and I feel it may be AquaMend.

PC Plumbing Epoxy

This stuff has a curing time of 12 minutes on paper, but in reality it's like 6 before it becomes utterly unworkable by hand. It's "A" is basically in the core of "B" so you cut the length of what you want and you mix it -- it doesn't get any easier than that. It may take some effort, and it does not become softer with heat. It's a putty that handles like a clay, and it doesn't stick too easily to damp hands.

After you mix it up into a consistent gray,

work quickly. I would recommend you cut only what you think you need. If you try to set some to the side in mixed form, it will harden and you will have wasted your money.

When I first used this on my Rubie's mask, I was disappointed with how difficult it was to sand. However you do have a measure of ease before your 12-minute curing time is up in which to file it and establish your primary shaping. If you are an absolute beginner, don't use this product but use AquaMend instead (see review below) as you are going to need a longer curing time.

You're not going to have any flex with this. It's extremely stiff and extremely hard. So think of what you're going to be applying it to.

It sands very well with an 80 grit hand sander. In cases where you build structure (e.g. Vader's inner eyelids) it may help having something that is harder which means (1) it's more forgiving for mistakes and (2) you can more carefully build out subtitles details if you use metal detailing files.

This is the right product for the right purpose, but for our general purposes it may be a bit too specialized. If you use it to fill cracks or pits, be sure that the material you are applying to is of similar hardness and wear resistance.

QuikPlastic

This is made by a competitor to the PC-epoxy products, and is a putty. It's "A" is basically in the core of "B" so you cut the length of what you want and you mix it -- and if you happen to have a heat gun, it is easier to knead. The outer core of the product is blue, and the inner core is white, but when you start kneading, it forms a light blue that will cure white. I do not believe it will turn yellow over time.

If you're used to Plasticine from your days as a kid, you'd be right at home here. It doesn't adhere to wet surfaces. It's like sticky plasticine. It won't stick to damp hands. I have used this on a Rubie's helmet as well as a Don Post Standard plastic helmet. Where you're dealing with this black vinyl type of plastic, it seems to do quite well.

Working with it with fingers is easy and straightforward, and it's very easy to use on rebuilding the Rubie's Vader's inner eyelids. Curing time is like 20 minutes. If it starts to harden before you're ready, a little bit of a heat gun softens it back up.

Using it to establish flat and smooth surfaces can be tricky. Using water as a resist (I don't know if denatured alcohol would help, but I'd rather not expose myself to too many chemicals) I used a waxy and smooth plastic spreader -- the pink-brown kind typically used for spreading automotive Bondo. I'd wet the QuikPlastic application and then use the spreader to press up against it. You do have to be careful because when you're pressing hard, you're squeezing water away, and your resist gets squeezed away too, so the QuikPlastic starts to stick to your spreader. I've basically tried establishing surfaces by pressing the spreader in, and then shifting it to the side by a few milimeters.

You can's spread this like a paste, unfortunately. And because the initial adhesion is light, any spreading with the spreader will cause the application to lift from the receiving surface.

I recommend this for a beginner working with plastic. It's easy to file and appears to take on plastic characteristics.

Now comes the good stuff....

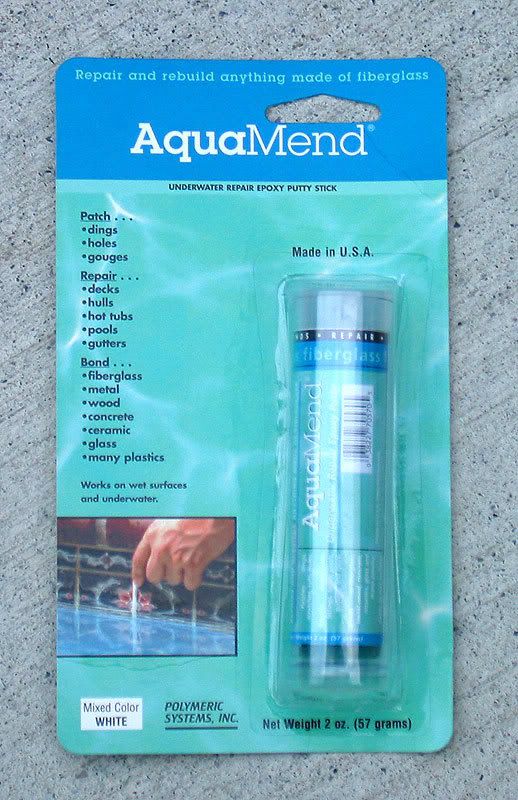

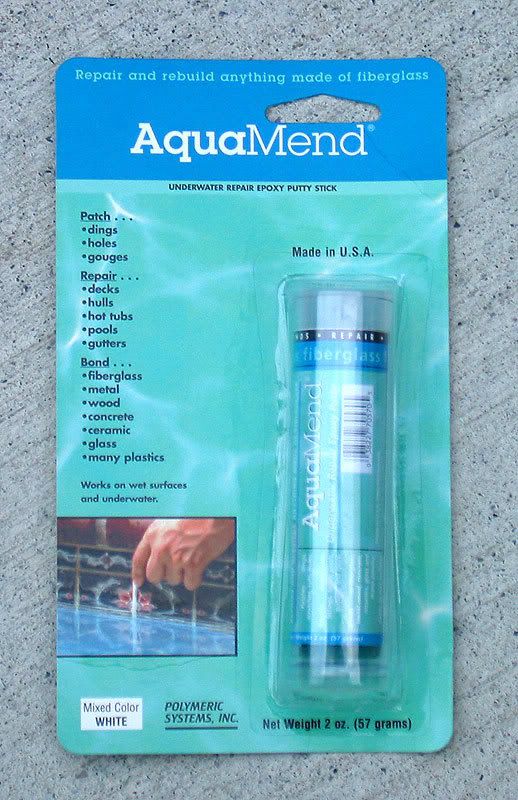

AquaMend

This was a recent discovery. For some of you who wonder why I don't deal with Bondo, it's because it's unfamiliar territory, as I'm a beginner who grew up with Play-doh, Plasticine and Blue Tack as a kid. I find it difficult to deal with "for a golf sized ball you'd squirt out this much" -- it leaves too much room for interpretation.

Now I'm looking for something that ideally works with fiberglass resins. It needs to bond like crazy and at the same time exhibit similar strength and flex characteristics and be easy to work with.

AquaMend is the marine fiberglass cousin to QuikPlastic, and similarly comes with an "A" in the core of "B" so you cut what you need and mix away. It cures white and stays white and doesn't go yellow over time. It reminds me of PC-11 but whereas PC-11 was a difficult-to-control stick-like-poodoo paste, PC-11 is a lot like a slightly sticky Plasticine that smoothes out very well with water and yet has some of the rigidity of a clay.

I can't say enough good things about AquaMend. It will sag a little under its weight, but with a curing time of 20 minutes (not one hour) you can come back in 5 minute intervals to check on the sag and make corrections. As it's about to cure 2/3 to 3/4 of the way, you can still manipulate it, and it won't sag. I have been using it to rebuild certain portions of the skull of a Vader faceplate to make the forehead seamless. It seem to stop sagging at around 12 minutes, so if you have patience, nurse it and cradle it and reshape it for that 12 minutes. As it starts getting stiffer, you can still press and thin out the application to cover a larger surface area (read: less sanding later).

While it's curing, there is still opportunity for smoothing out with wet fingers. I've not tried using a bondo spreader to press up and flatten it, but in its freshly mixed state it's soft, but nowhere nearly as sticky as PC-11 so wet hands can work it very well. The manufacturer claims it bonds to most plastics, which makes me wonder why QuikPlastic is necessary at all. It may be that it is harder than Quikplastic when it comes to sanding. I've used an electric hand sander and it responds well, I've not yet worked it with a file, but QuikPlastic is very shapable with files.

Physically, AquaMend behaves a bit like the resin used in fiberglass application. It seems to have a bit of flex too, which is good. It also has bonded with the fibgerlass and my initial testing with prodding of fingers seem to show very reasonable cohesion. I've not ascertained at this time whether it's bonding is as strong as PC-11's or not, but a point to note is that if you have a rough surface and if you press the PC-11 putty into it, it will have more to grip.

I do get a unverified sense that while PC-11 might be a bit stronger in cohesion than AquaMend (it is possible that pastes have better cohesion than putties), AquaMend has superior handling due to it being a putty, so you get the handling bliss of a putty but the resultant physical properties of PC-11. I love PC-11 because it becomes "one" with the fiberglass. When AquaMend hardens it looks like plastic or clay but when you sand it, that is where it's potential comes out.

AquaMend is

less expensive than PC-7 per item, though it is possible that volume-wise you also get a bit less. However, I think Aquamend has a lower cost per use.